During this important international pharma industry event, SEA Vision will be showing off the most innovative solutions to meet the needs of pharmaceutical industry customers at its booth, in particular:

- Automated Smart Line Clearance: innovative Line Clearance solution powered by revolutionary AI algorithms developed by ARGO Vision, installed on a Cody packaging machine developed by Marchesini Group

- Serialization of blister primary packaging and aggregation to cartons: Software solution installed on a complete Integra Blister Packaging Line designed by Marchesini Group

Also, on stand 60c20, Marchesini Group will be exhibiting the COMPACT 24, a monobloc machine for filling and capping bottles for tablets, capsules or pills, which has been further upgraded in the last few months in light of the market’s strong interest in this solution.

The monobloc, constructed by the Tonazzi-Vasquali division, stands out for its innovative magnetic conveyor system enabling totally independent handling of every single bottle, and its new rotary twin flaps which facilitate the passage of the product into the bottle.

Another new feature is the option to install the new VALIDA technology, developed in close partnership with SEA Vision. This system of extremely high quality cameras detects the individual product, fully inspects it (shape, weight, size and colour), and rejects products on an individual basis, thanks to extremely close interaction with the machine’s PC system.

Smart Line Clearance: safer and more efficient, with AI algorithms

Smart Line Clearance: safer and more efficient, with AI algorithms

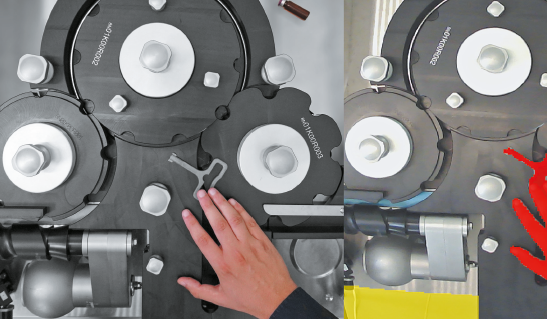

At booth, SEA Vision will be showing off its new AI-powered Automated Line Clearance solution, installed on a CODY machine designed by Marchesini Group.

Everybody knows that the line clearance processes are crucial stages performed before production begins. The objective is to ensure that equipment and work areas are clean/free from any residual materials or documents. However, these very important phases still require the manual intervention of operators to perform specific paper-based tasks and activities with consequent risks related to human error.

The need for greater safety and smoother processes are the main driver of SEA Vision’s Smart Clearance technology. This brand-new solution (already launched at Achema on August 2022) is driven by AI algorithms to automate the line clearance procedures while avoiding errors, reducing the time required, and boosting the OEE of production lines.

Part of the Industry 4.0 software suite yudoo, Smart Clearance Technology is capable of performing automatic and accurate inspection of the packaging line working areas using cameras and sensors.

These devices are all managed by innovative smart acquisition system powered by AI algorithms which analyse the inspected scenes in depth and in real time, immediately identifying any machine parts out of position, foreign objects, or products passing through the machine. The result is that clearing and cleaning phases are digitized, and at the same time the checking phase is automated.

The AI system is also able to overcome the limitations of traditional vision systems in terms of glare, shade, or differing light conditions. The advantages are manifold: more accurate inspections in real time, shorter changeover times, added safety for the business’s quality processes, and enablement of Industry 4.0 factory digitization.

Primary pack serialization and aggregation

SEA Vision experts will demonstrate to visitors the latest developments in our serialization and aggregation systems which are applicable to the primary packaging. The new blister Track & Trace technology is a brand-new solution, launched on the market for the first time on August, during the Achema trade fair.

Designed to serialize the blister primary packaging and perform aggregation with cartons, it is a strategic innovation to improve the safety of products during their distribution, fighting counterfeiting especially in countries where drugs are dispensed in single doses.

SEA Vision S.r.l.

Headquarters: Via Treves 9 E 27100 Pavia (PV) Italy

Maria Grazia Preda

marketingdept@seavision-group.com

Tel.: +39.392.1771730

www.seavision-group.com