Marchesini Group opened the doors of its Headquarters to show customers the latest technologies developed in the field of pharmaceutical product processing and packaging. The event took place in Bologna (Italy) and it was organised in conjunction with the exhibition “Pharmintech powered by Ipack-Ima”, helded in Milan from 3 to 6 May.

During the events the Group showed a vast range of machines and services for the pharmaceutical industry, but also its latest innovations in the field of sustainability and the progress made in robotics. The partner Eyecan, a start-up originating from a University of Bologna spin-off, with which the Group has recently developed a solution using Artificial Intelligence, was present at the event with a demonstration of how AI can be involved in robot picking applications to facilitate the identification and picking of any product within the packaging cycle.

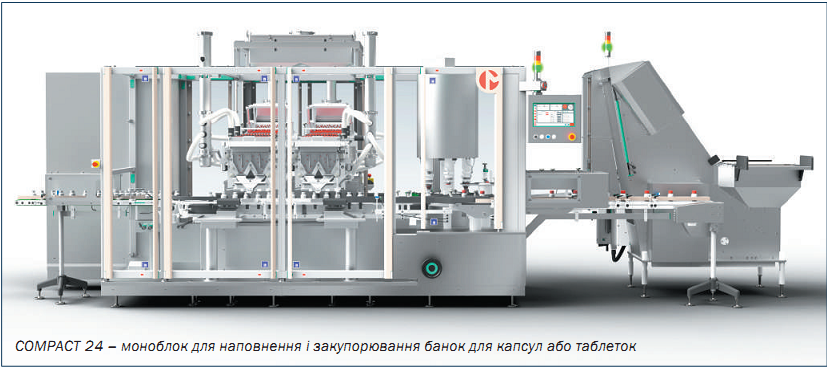

In terms of the development of new machines and lines, the Group presented the COMPACT 24: a monobloc machine for filling and capping bottles for tablets, capsules or pills, which has been further renewed in the last few months in view of the market’s strong interest in this solution.

The machine, constructed by the Tonazzi-Vasquali division, has a distinctive innovative magnetic transport system enabling totally independent handling of every single bottle, thanks both to new rotary twin flaps which facilitate the product’s passage into the bottle, and, above all, the new VALIDA technology, developed in close cooperation with the partner Sea Vision. This system of extremely high quality cameras collects the individual product, totally inspects it (weight, shape, size and colour) and rejects products on a one-by-one basis, thanks to extremely close interaction with the machine’s PC system.

Other innovations included a line for packaging products in stickpacks, comprising a Schmucker MT1300 12-lane stick packaging machine, a stacking and counting system and an MA80 cartoner. Specifically, this line is designed to process PP-based packaging materials (with and without PE) such as 100% recyclable plastic monomaterials like OPP or BOPP with a metallised intermediate layer.

As well as this solution, visitors viewed another line consisting of a CMP Phar.ma machine able to inspect up to 400 vials per minute, an RL-F800 extremely high-speed labelling machine with a rotary star wheel infeed system and rotary roller conveyor - designed by the Neri division - and, to conclude, a TM3 machine for bundling vials in trays, with counter function and SEA Vision camera for optical inspection of tray contents.

The Open Door even also featured liquid filling solutions, including an ML636 monobloc comprising a vial cleaning station and a filling and capping machine for drinkable products (multivitamins, lactic acid bacteria, etc.), with extremely high speed production and an electronic dosage system with mass flow measuring. Visitors also were able to view an extremely versatile ML642 alternating motion filling and capping machine suitable for various types of products, including syrups, spray solutions, injectables (e.g. for veterinary use) or diagnostic products, as well as an OPTO150 monobloc for packaging all the main types of ophthalmic products on the market, able to combine various functions including a vial cleaning unit, dosing, 100% weight checking, nitrogen injection and capping.

The innovations also included three solutions from the Dott. Bonapace brand: an automatic capsule filler able to produce up to 3000 capsules/hour, designed to dose different products into the same capsule, a rotary tablet press for R&D laboratories and small production lots and, last but not least, a turbo-emulsifier for pharmaceutical products.

To conclude, there was no lack of secondary packaging and end-of-line solutions: the Group exhibited two high-speed continuous motion horizontal cartoning machines, the first - MA 260 - featuring simple, basic size change, as well as two hoppers for easier, more precise insertion of the product and leaflet inside the carton, and the second - MA 200 - designed to package products in very large cartons. On show, there were also two automatic labelling machines produced by the Neri division, one of them - BL-A525CW - with integral checkweigher, for dynamic weighing and checking of cartons. The BL-A415S, a more compact labeller enabling multiple functions to be combined in the same machine (T&T and tamper evident seal) will also be displayed in operation. Both these solutions are designed to accommodate Track and Trace applications and are able to apply an optical vignette label and self- adhesive tamper evident seals to cartons at high production speed.

adhesive tamper evident seals to cartons at high production speed.

The final innovation is a case-packer and palletiser monobloc equipped with a state-of-the-art robot (X-Fly) with parallel architecture, reflecting the Group’s commitment to the research and development of unconventional robotic solutions.